Technology & Innovation

Superior is a leader in multiple aluminum wheel technologies and innovative solutions which add value for many OEMs across the globe.

ALULITE™

Patented mass reduction technology

- Significant mass savings versus traditional cast wheels

- Enhanced styling concepts available

- Potential improved wheel ride and handling characteristics

- Low Aero Drag Designs

DECOTECH™

Patented specialized wheel finishing

- Limitless colors

- Many textures available

- Brushed metal effects

- Fine details

- Current OEM production

.png)

.png)

Aero Styling

Environmental conservation

- Increased range for both EV's and ICE powered vehicles.

Multi-axis Milling

Specialized wheel finishing

- Enhanced styling options

Flow Forming

Lightweighting technology

- Reduced mass

- Increased material strength

Laser Etching

Patent pending specialized wheel finishing

- Extensive color palette

- Multiple accent colors

- Eliminates development/testing of new powder primer colors

- Reduces cycle time compared to etching to substrate

Lightweight Performance Casting (LWPC)

Lightweighting Technology

- Reduced rim mass

- Increased material strength

.png)

Pad Printing

Specialized wheel finishing

- Extensive color pallet

- Approved OEM process and materials

PVD

Patented specialized wheel finishing

- Dark PVD

- Bright machined PVD (Bright or Dark pockets)

- Multiple tinted PVD colors

- Matte finish PVD -- multiple gloss levels

- DecoTech™ compatible

- Current OEM production

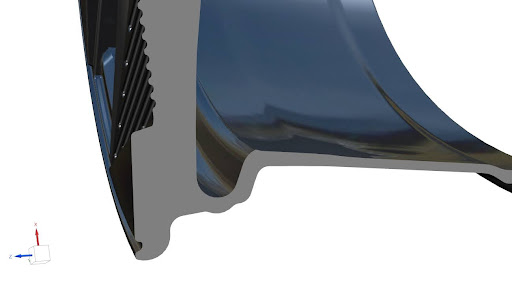

Undercut Machining

Lightweighting technology

- Significant mass reduction potential

- OEM approved

- Enhanced styling potential

Tinted Clear Coat

Patent pending specialized wheel finishing

- Applies over machined face or 3D surfaces such as polished or PVD finishes

- Liquid and powder materials available

- Multiple colors under development

Satin and Matte Clear Coat

Patent pending specialized wheel finishing

- Applies over machined face or 3D surfaces such as polished or PVD finishes

- Existing liquid mattes are applied as 2- or 3-layer systems

- Powder technology available

- OEM approved systems

Paint Masking

Specialized wheel finishing

- Advanced masking techniques use specialized "drop-in" rigid masks and flexible "tape-on" masking for intricate multi-color concepts.

- Multi-gloss concepts

- Current OEM production

3DPC™

Specialized wheel finishing

- Uses less material and energy vs. conventional systems

- "Green" Technology

- Textured finish capable

- Extensive color choices

- Matte and high-gloss finishes

R4™ & R4ZERO™

Environmental conservation

- "Green" wheel with certified low CO2 materials and processes